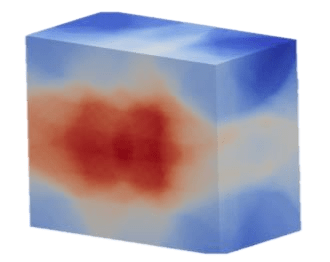

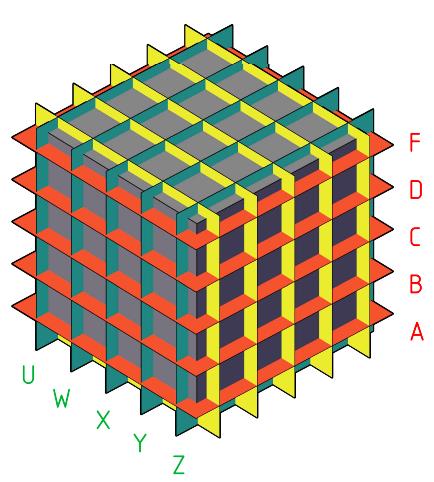

“Concrete tomograph” – strain and temperature evolution at early stage

This challenging experiment involved a concrete cube embedded with optical sensors oriented in three directions (X, Y, and Z). The total number of 75 sections for strain and 25 sections for temperature measurements were created without disturbing the structural performance of the concrete. The research aimed to analyse the spatial behaviour of the massive element during the hydration and shrinkage process, including temperatures and heat transfer.

DFOS Sensors Installed: Optical fibre in acrylate coating

Project challenges

Benefits of using the DFOS monitoring system

Results of using the DFOS monitoring system

The 3D network of strain and temperature Nerve-Sensors was successfully embedded inside the cube concreted with self-compacting concrete. The installation process was challenging as there was no reinforcement inside the element. The purpose of the cube (35 x 35 x 35 cm) was to simulate the behaviour of a massive concrete element during its early age (hydration process). Finally, the spatial picture of thermal-shrinkage strains was obtained in all directions.

Technical specifications

Example results

Recomendations (optional)

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

John Doe

Project partner