Plastic strains in steel anchorages: axial tension test

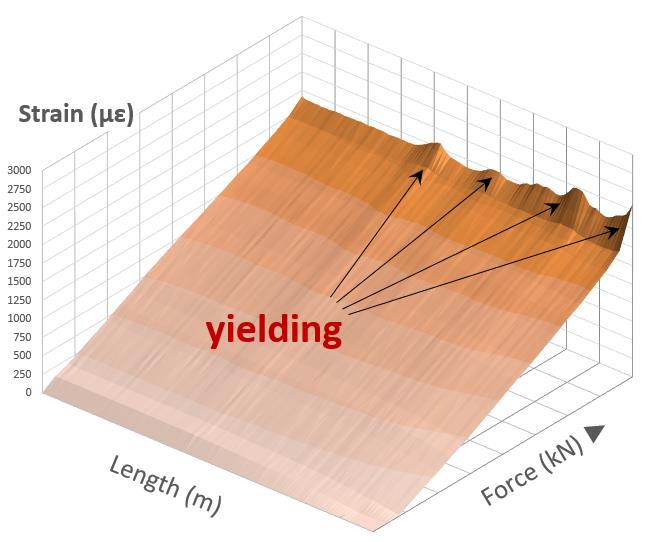

The research performed in the laboratory of AGH University of Science and Technology was focused on the analysis of the structural performance of steel ground anchorages. The challenge in this project was to measure not only uniform elastic strains caused by axial tension but also extremely high and unregular strains during yielding. Thanks to DFOS strain sensors, it was possible to analyse this process in a very detailed way, e.g. indicating the areas where yielding starts.

DFOS Sensors Installed: Optical fibre in acrylate coating

Project challenges

Benefits of using the DFOS monitoring system

Results of using the DFOS monitoring system

One of the research goals was to monitor the yielding process of steel anchorages during their axial tension tests. Thanks to distributed fibre optic sensing, it was possible to observe this phenomenon both in length and time domain, creating a 3D plot as shown below. In the initial load steps, uniform distribution of strains was observed over the entire length, but later, after exceeding the value of 2000 µε, the local yield zones were formed and identified by the DFOS-based system.

Technical specifications

Example results

Recomendations (optional)

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

John Doe

Project partner