Thermal-shrinkage strains of GRP composite pipe in the laboratory

The glass fibre reinforced polymer (GFRP) pipe with a length of 4 m, a diameter of 270 mm and wall thickness of 11 mm, installed on a rigid steel frame in a cantilevered scheme, was tested under laboratory conditions. Surface strain was measured with the EpsilonSensor, while vertical displacements with the 3DSensor. The system was also designed to detect local events: mechanical crack causing stress concentration and simulated temperature effects (leakageand compressed air).

DFOS Sensors Installed: EpsilonSensor and 3DSensor

Project challenges

Benefits of using the DFOS monitoring system

Results of using the DFOS monitoring system

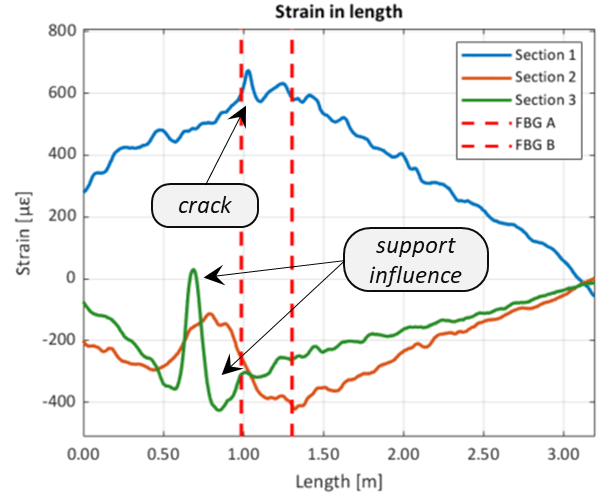

The graph presents example strain results from bending tests, revealing both mechanical damage (cracking) and the localized impact of spot support. In other tests, cold water leakage through pinholes in the pipe wall, along with the application of compressed air, were detected due to localized temperature variations. Measurements were conducted under the monitoring of reference Fiber Bragg Gratings (FBGs).

Technical specifications

Example results

Recomendations (optional)

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

John Doe