Measurements of a railway line above the substrate strengthened with slurry walls

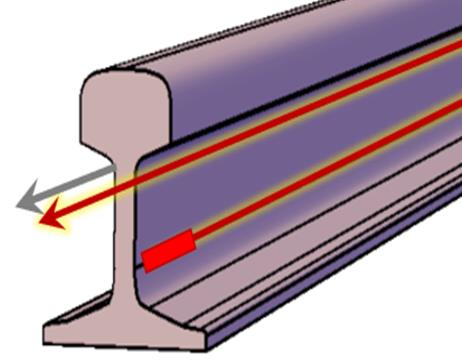

This unique research aimed to investigate the fatigue performance of the railway lines above the strengthened substrate. The strengthening slurry walls were made of a new material: fibre reinforced concrete mixed with the ground. Vertical and horizontal EpsilonRebars were installed inside the walls, and optical fibres were glued directly to the steel rails. The measurements were performed statically and dynamically during millions of cycles to observe long-term effects.

DFOS Sensors Installed: EpsilonRebar

Project challenges

Benefits of using the DFOS monitoring system

Results of using the DFOS monitoring system

The most important part of the research was focused on slurry walls – based on horizontal and vertical strains, the cracks morphology of the walls was fully reflected. However, exciting phenomena were also observed on the steel rails, including tension and compression zones and local effects of wheel pressure.

Technical specifications

Example results

Recomendations (optional)

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

John Doe