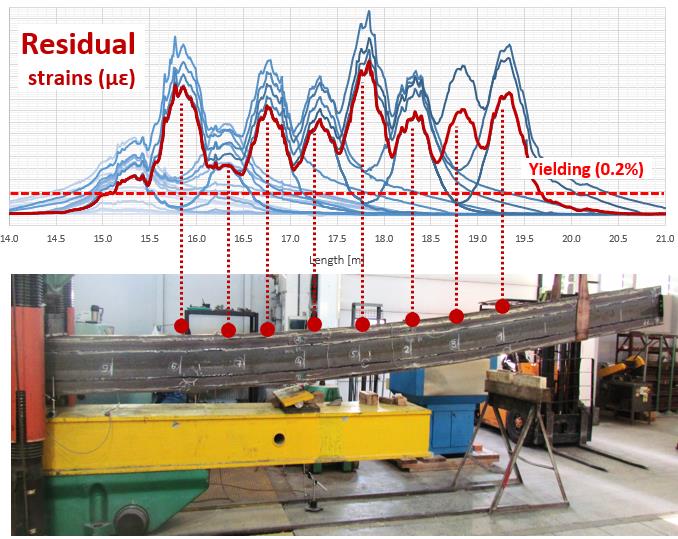

Steel girders during mechanical load tests: elastic and plastic strains

A number of steel girders designed for bridge applications were investigated in laboratory conditions during mechanical tests. The research includes MCL girders as well as I- and H-beams. The challenge in this project was to measure extremely high strains, exceeding the range of elastic behaviour significantly. Thanks to DFOS strain sensors, it was possible to analyse the yielding process up to 20 000 µε in tension and 10 000 µε in compression.

DFOS Sensors Installed: Optical fibre in acrylate coating

Project challenges

Benefits of using the DFOS monitoring system

Results of using the DFOS monitoring system

One of the research goals was to monitor the yielding process of steel girders, both in their compression and tension zones. The network of DFOS strain sensors installed within the structural elements allowed us to obtain a comprehensive picture of strains for different load schemes and force values. The figure below shows the example result of strain distributions for selected girder. The red line corresponds to residual strains, which remained after tests were completed.

Technical specifications

Example results

Recomendations (optional)

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

John Doe

Project partner