Strains and cracks in a new type of slurry wall: research field (1)

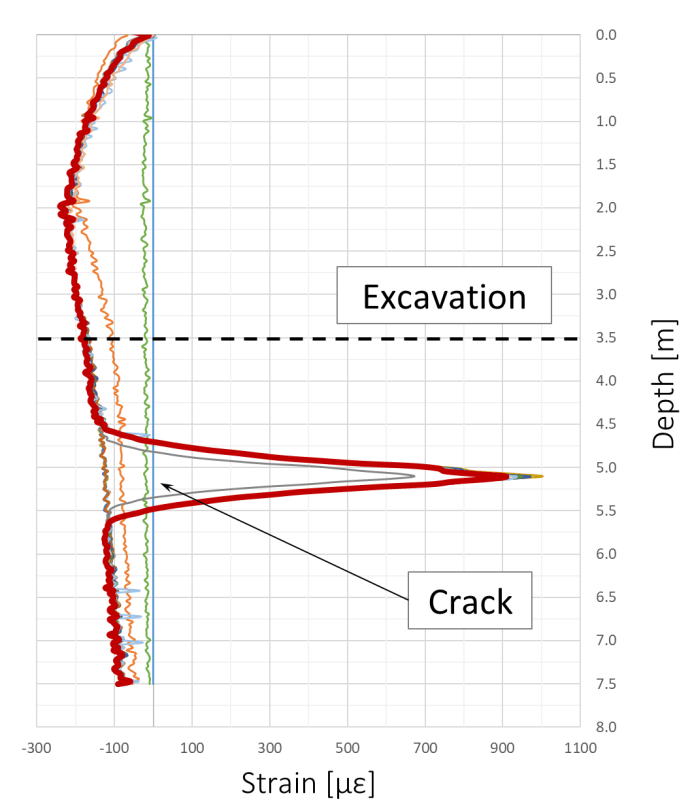

The subject of the project was the slurry wall made of a new type of material: fibre-reinforced concrete mixed with the ground. As this technology must be carefully checked before use, the EpsilonRebars were used for this purpose. The structural performance of the wall was monitored during deepening of the excavation area as well as load tests. Thanks to Nerve-Sensors, it was possible to detect cracks and fractures invisible to other techniques.

DFOS Sensors Installed: EpsilonRebar

Project challenges

Benefits of using the DFOS monitoring system

Results of using the DFOS monitoring system

The slurry wall was loaded using concrete slabs. The figure shows example strain profiles obtained from EpsilonRebar during subsequent load steps. It can be clearly observed that a fracture inside the wall was detected under the excavation level. As there was no access for visual inspection, no other technique was able to provide such key information.

Technical specifications

Example results

Recomendations (optional)

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

John Doe

Project partner