The 2nd bridge in Germany with embedded strain and crack distributed sensors

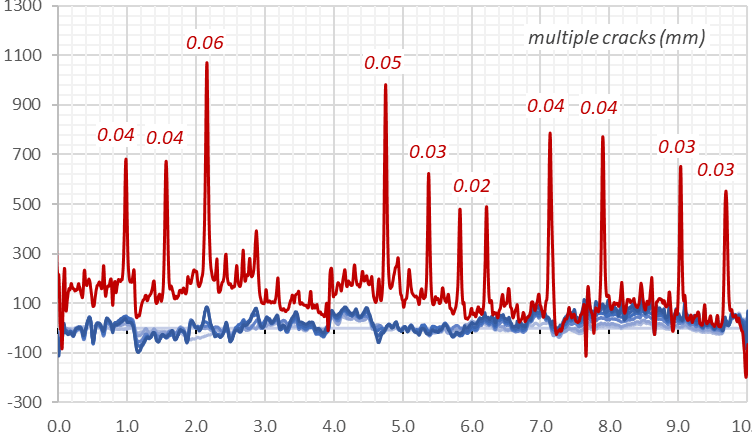

EpsilonSensors were embedded within the concrete slab of the bridge in question, making it the second smart structure of this type created in Germany. The DFOS-based monitoring system was designed to measure strain profiles in the concrete and detect all the microcracks formed during early-age concrete hydration. Reference spot thermistors were used to measure unregular temperature distributions and then to compensate for DFOS strain results.

DFOS Sensors Installed: EpsilonSensor

Project challenges

Benefits of using the DFOS monitoring system

Results of using the DFOS monitoring system

Three EpsilonSensors (ES) were installed by tightening them to the existing reinforcement. The measurements done the day after concreting allowed us to identify all microcracks formed due to the shrinkage of the constrained concrete.

Technical specifications

Example results

Recomendations (optional)

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

John Doe

Project partner