Steel-concrete railway bridge: strains and cracks during load tests

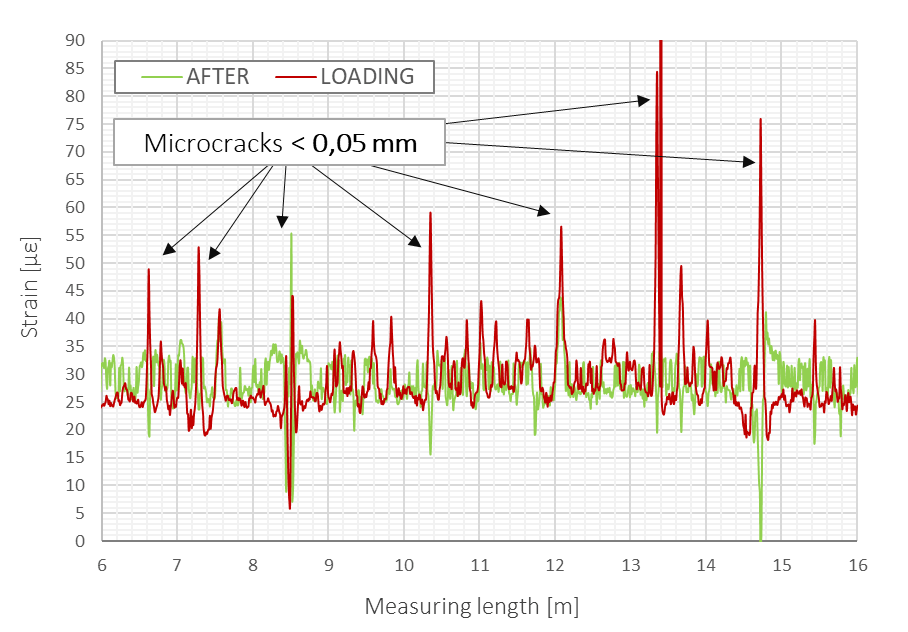

The composite (steel-concrete) bridge in Dąbrowa Górnicza was designed according to a new approach and put into service in 2019. This is why verification of its structural performance under real operating conditions was of significant importance. The bridge was equipped with DFOS strain sensors, installed both on the concrete and steel surfaces. The measurements during load tests allowed for detailed analysis of the deformation state, including the detection of all microcracks.

DFOS Sensors Installed: Optical fibre in acrylate coating

Project challenges

Benefits of using the DFOS monitoring system

Results of using the DFOS monitoring system

Distributed fibre optic strain sensors were installed at the bottom and top flange of the steel girder, as well as at the side surface of the concrete. Such a sensing system setup allowed for detailed analysis of the interaction between these two materials and validation of a new design approach. Distributed measurements taken during load tests (locomotive load) prior to commissioning enabled the detection of all microcracks along the girder length. However, most of them were closed after removing the load, which was very important information for the engineer responsible for the long-term safety and durability of the bridge.

Technical specifications

Example results

Recomendations (optional)

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

John Doe

Project partner