EpsilonPeak

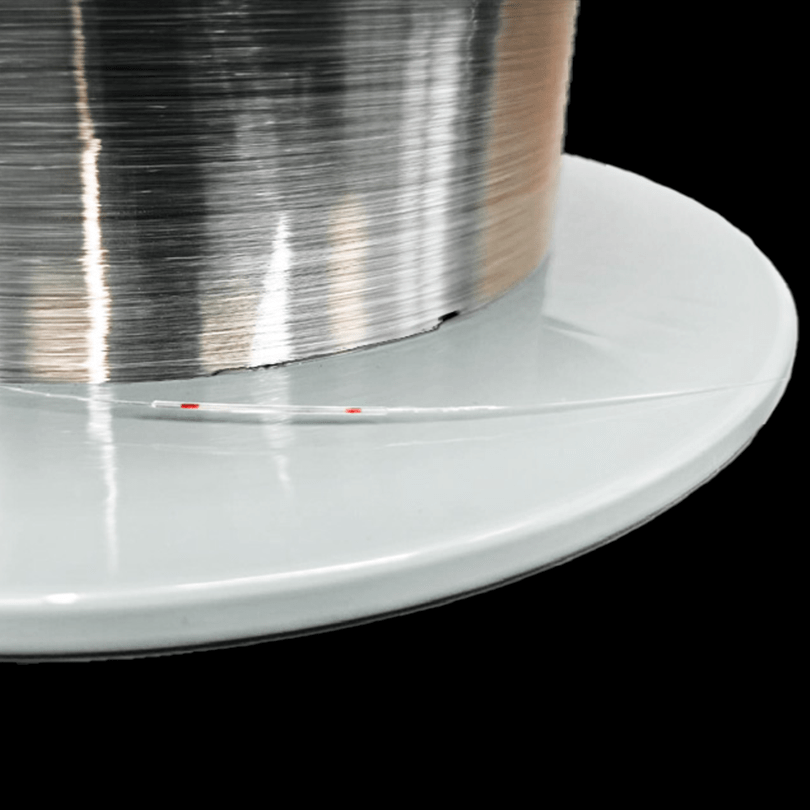

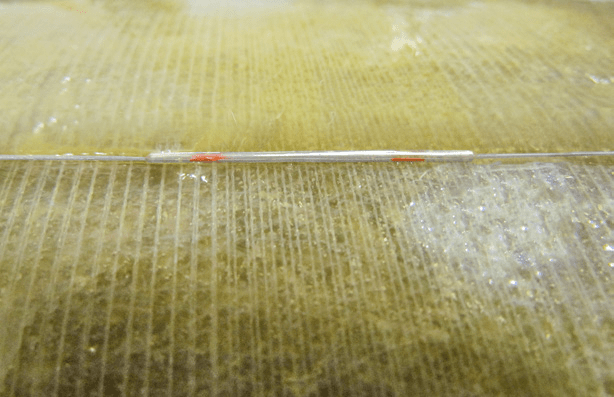

The first Fibre Bragg Grating (FBG) – EpsilonPeak averaging the structural strains along its base (10 mm as standard) for accurate and repeatable measurements with high sensitivity and range.

The unique FBG sensor without spectrum splitting that allows the measurements and control of non-homogenous materials such as Fibre Reinforced Polymers (FRP) or concrete.

The unique FBG sensor without spectrum splitting that allows the measurements and control of non-homogenous materials such as Fibre Reinforced Polymers (FRP) or concrete.

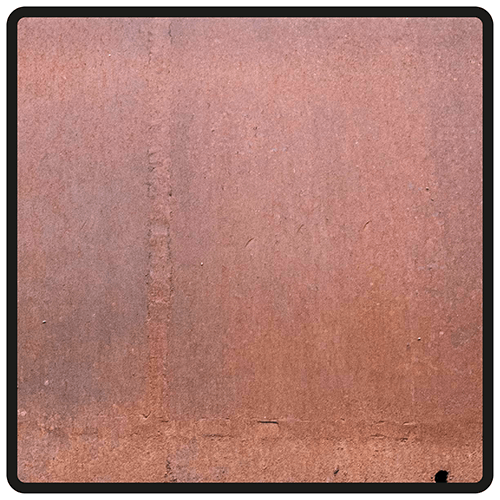

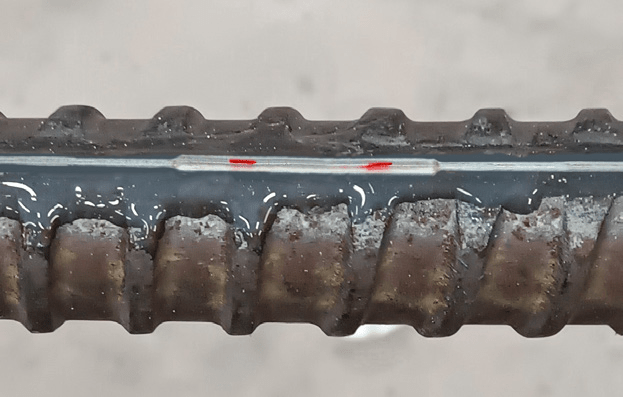

There is also a possibility to measure steel in the plastic deformation range (yielding), where strains perpendicular to the optical fibre axis can occur as a result of non-uniform strain field.

EpsilonPeak Advantages

Physical Quantities Measured

Strain Sensing

Temperature Sensing

Typical Materials

Concrete

Steel

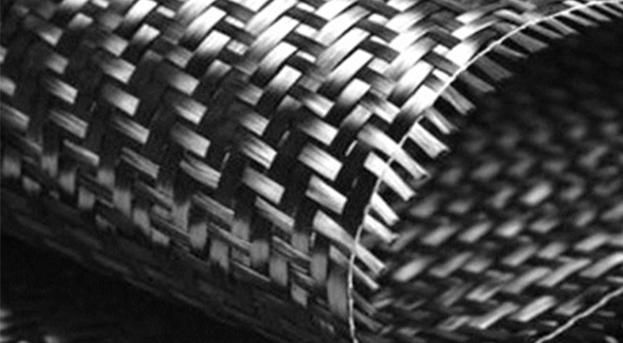

Composite

EpsilonPeak Application Areas

Structures | Bridges | Piles | Dams | Pipelines | Tunnels | Railways | Earthworks | Laboratories… and more

How our FBG sensor works vs. competition

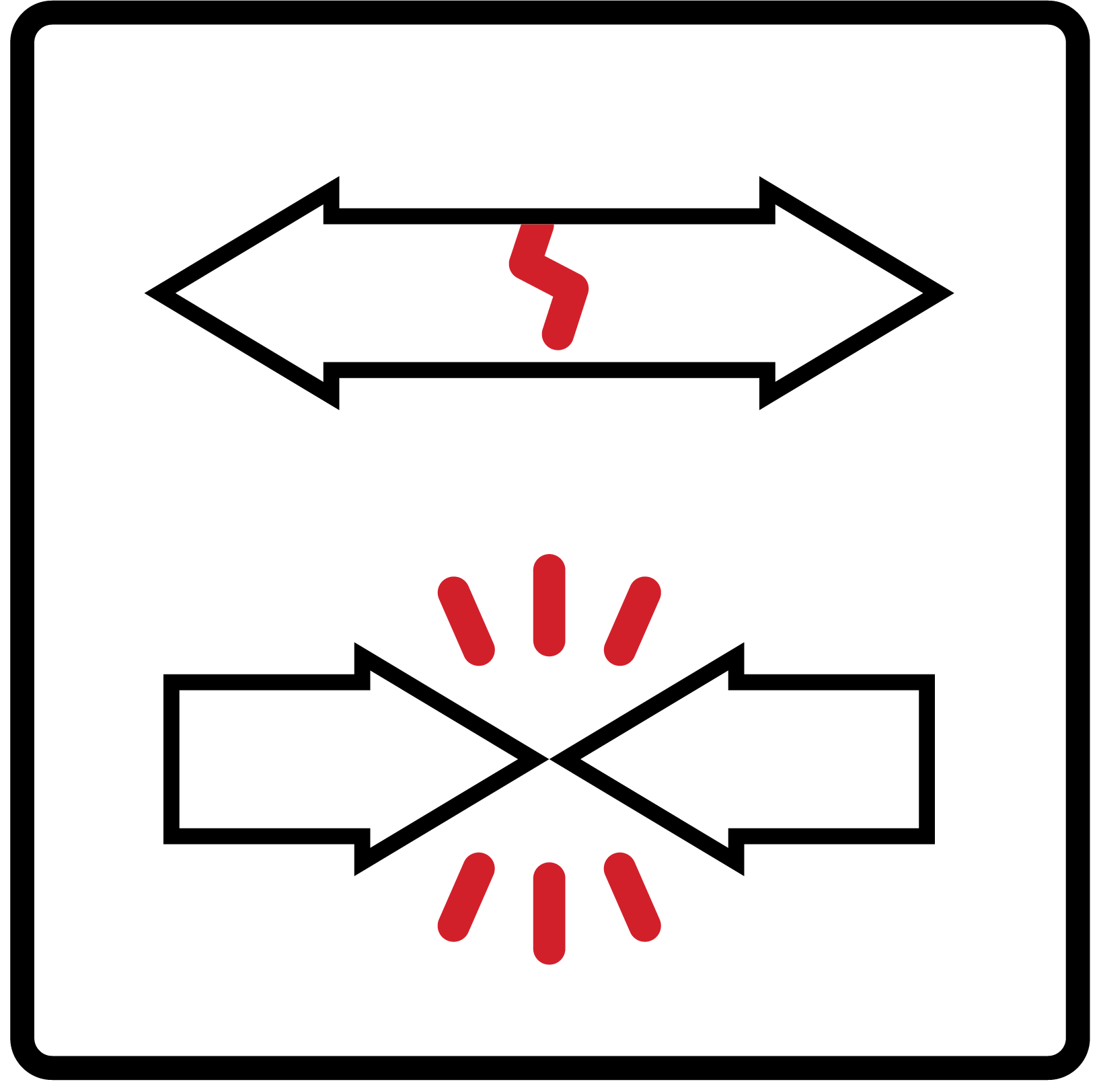

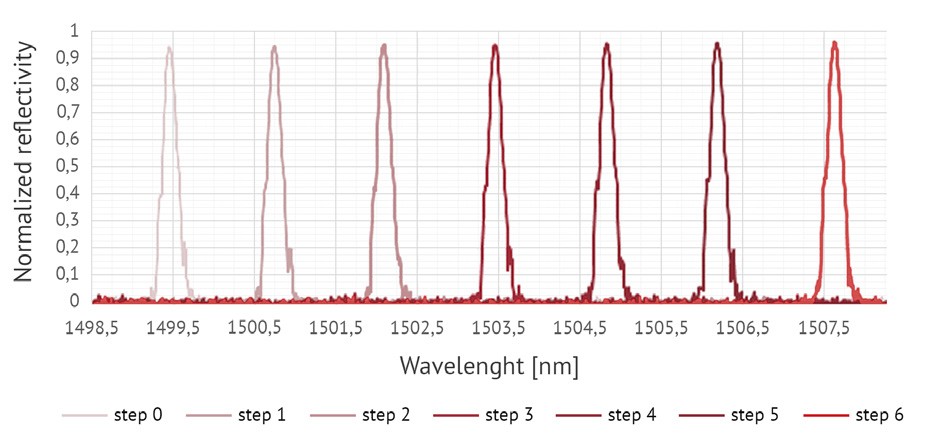

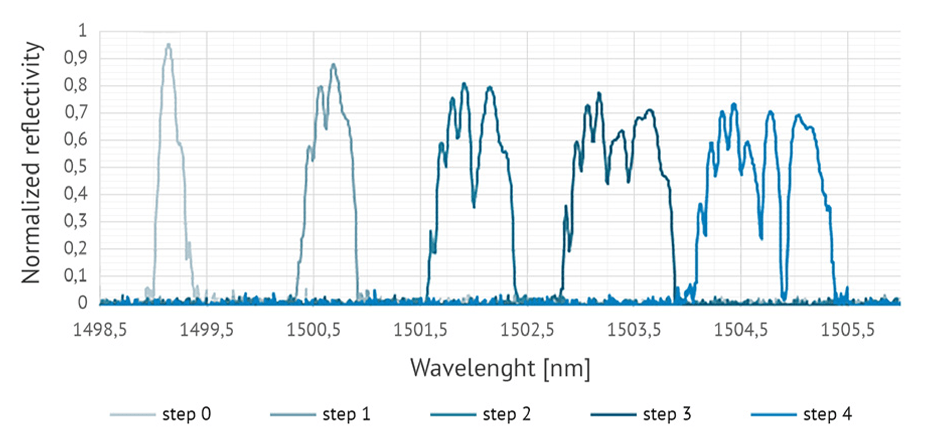

Homogeneous strains along the FBG sensor cause proportional changes in its period (Λ), shifting the spectral peak to shorter or longer wavelengths.

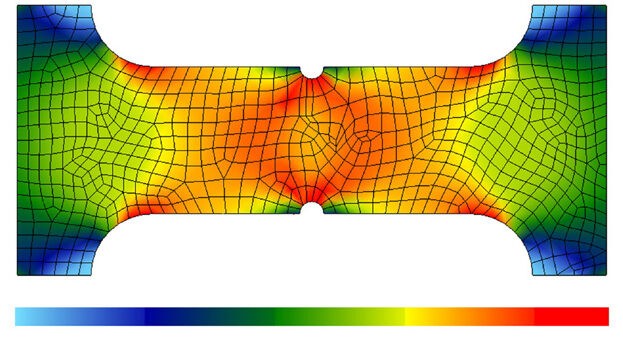

Homogeneous strains along the FBG sensor cause proportional changes in its period (Λ), shifting the spectral peak to shorter or longer wavelengths. However, homogeneous strain are rare in practice. Materials like FRP, concrete, or steel under plastic deformation create non-uniform strain fields, leading to broadened, split, or deformed spectral peaks, making accurate and trusted strain measurements impossible. Our sensor averages these non-uniform strains over the grating length, enhancing measurement range and reliability, similar to electrical foil strain gauges.

Our sensor – EpsilonPeak

Competition

Period in non uniform strain

EpsilonPeak Technical Specifications

Optical properties

Range of available central Bragg wavelengths1

1407-1607 nm

Accuracy of central Bragg wavelength

±50 pm

Full Width at Half Maximum

< 150 pm

Side Lobe Suppression Ratio

15 dB

Type of FBG

uniform/apodised

Fibre outer diameter (excl. coating)

125 μm

Fibre type2

bend-insensitive photosensitive

Sensing properties

Physical length of FBG

1-10 mm

Number of FBGs on one fibre

customised

Strain range3

from ± 4000 to ± 50 000 με

Strain accuracy

not worse than 0.5% of the measurement range

Thermal compensation

external/second FBG

Working temperature

from -30 to +70°C

Fibre termination4

none, bare fibre

Calibration card5

is added to each sensor

1 Exact wavelengths available upon request

² As standard, different types of optical fibres available upon request

3 As standard for bend-insensitive photosensitive fibre. Strain range may differ

for different types of optical fibres

4 As standard, different fibre terminations available upon request

5 Each FBG is carefully checked. Each sensor is supplied with a calibration card

containing an equation that allows the conversion of the central wavelength

into strains

² As standard, different types of optical fibres available upon request

3 As standard for bend-insensitive photosensitive fibre. Strain range may differ

for different types of optical fibres

4 As standard, different fibre terminations available upon request

5 Each FBG is carefully checked. Each sensor is supplied with a calibration card

containing an equation that allows the conversion of the central wavelength

into strains

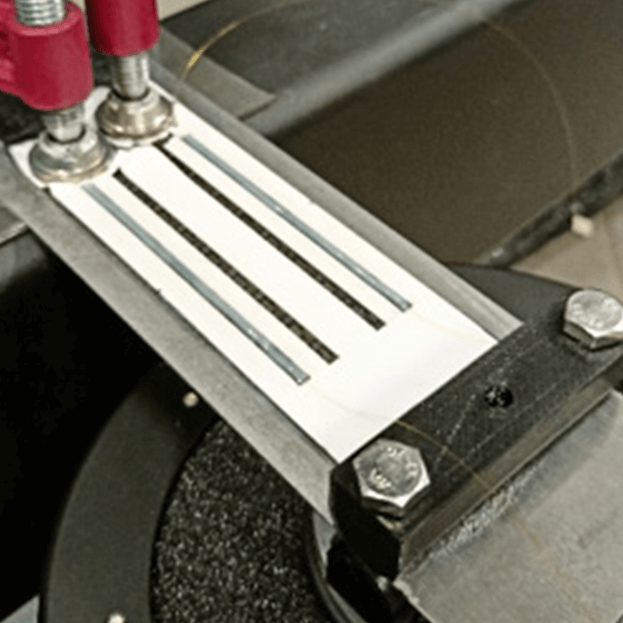

Yielding steel and composite (FBG application examples) and strain map

EpsilonPeak Installation

Each installation should be designed individually, taking into account specific requirements and local conditions. However, there are three typical methods:

Gluing directly onto the surface

Bonding directly to sanded, cleaned and degreased structural surface

Installation during composite production in the infusion and pultrusion proces

EpsilonPeak FAQ

How is the fibre with FBG terminated? Is it possible to modify the connectors?

What is the minimum physical distance between consecutive FBGs?

From what wavelength range can the centre wavelength be selected? Is it only the III telecom window, or ~850 nm also?

What interrogators does the FBG sensor work with?

What type of FBGs do you produce?

Is it possible to modify the length of the FBG?

How long can the entire sensor system be?

What is the possible operating temperature range of the sensor?

What is the maximum length of the inlet patchcord between the interrogator and the sensor?

How to install FBG on structural elements?

What are the lengths of standard FBG?

How many FBGs can be made on one optical fibre?

How to ensure repeatable installation of successive FBGs?

Can your FBG be used to measure strain in a static tensile test of steel?

Can I use your FBG to monitor composite materials?

Can I use your FBG in tests that take into account cracking of the material under test?

How to convert the wavelength of the FBG into strains?

Can FBGs be used for dynamic measurements?