EpsilonRebar

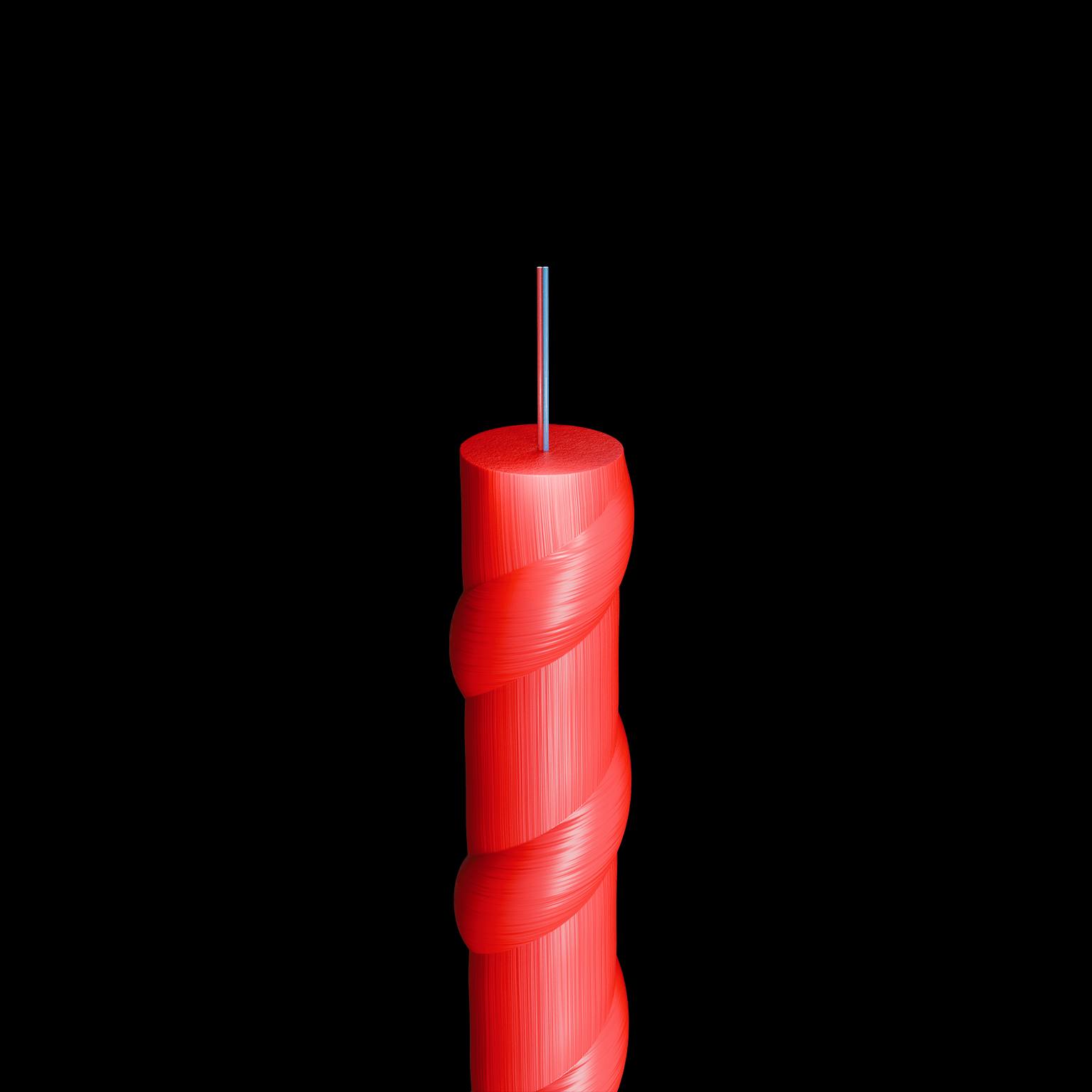

The world’s first DFOS sensor with a strain range of up to 2% and a high elasticity modulus (E = 50 GPa) designed to be used as a sensor and reinforcement at the same time.

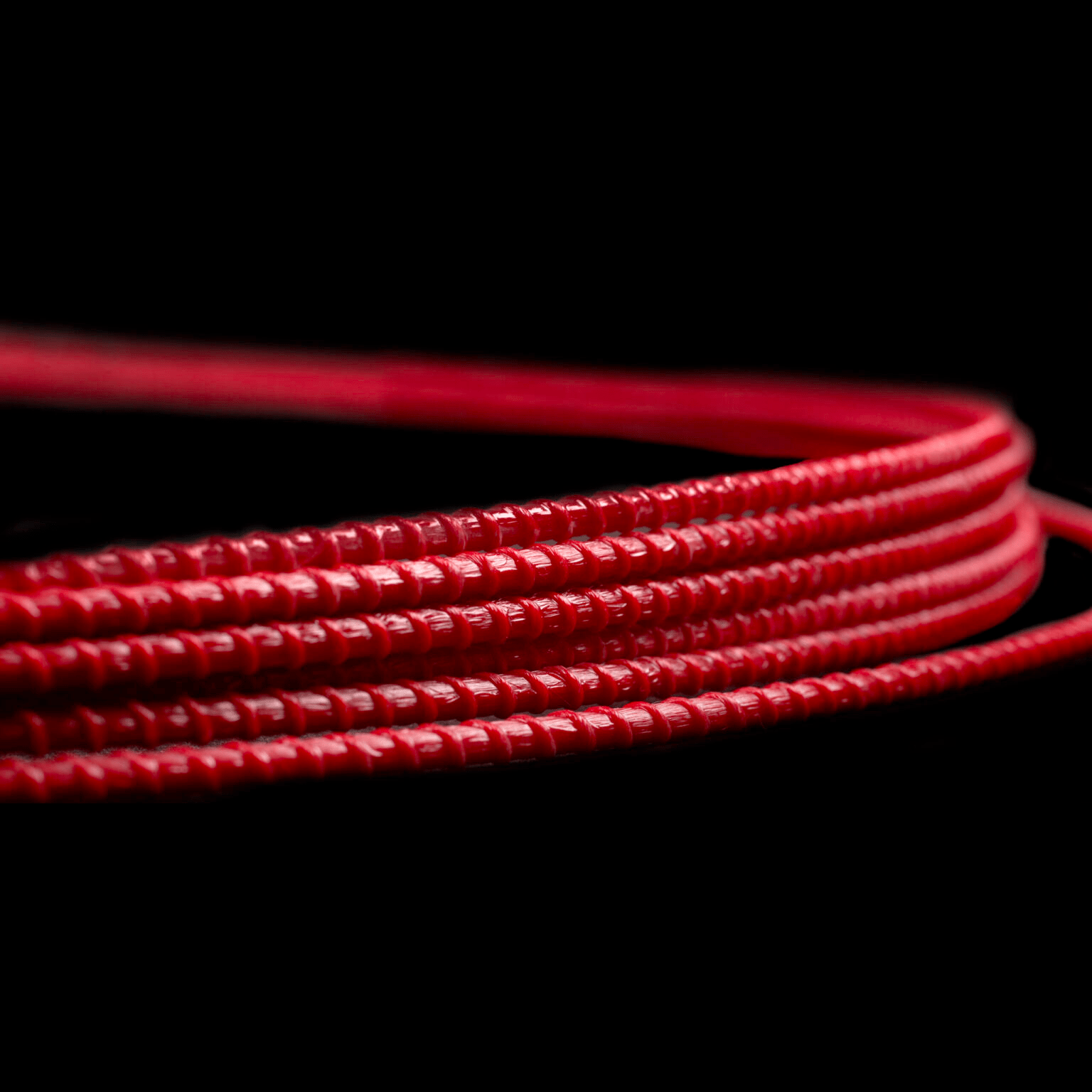

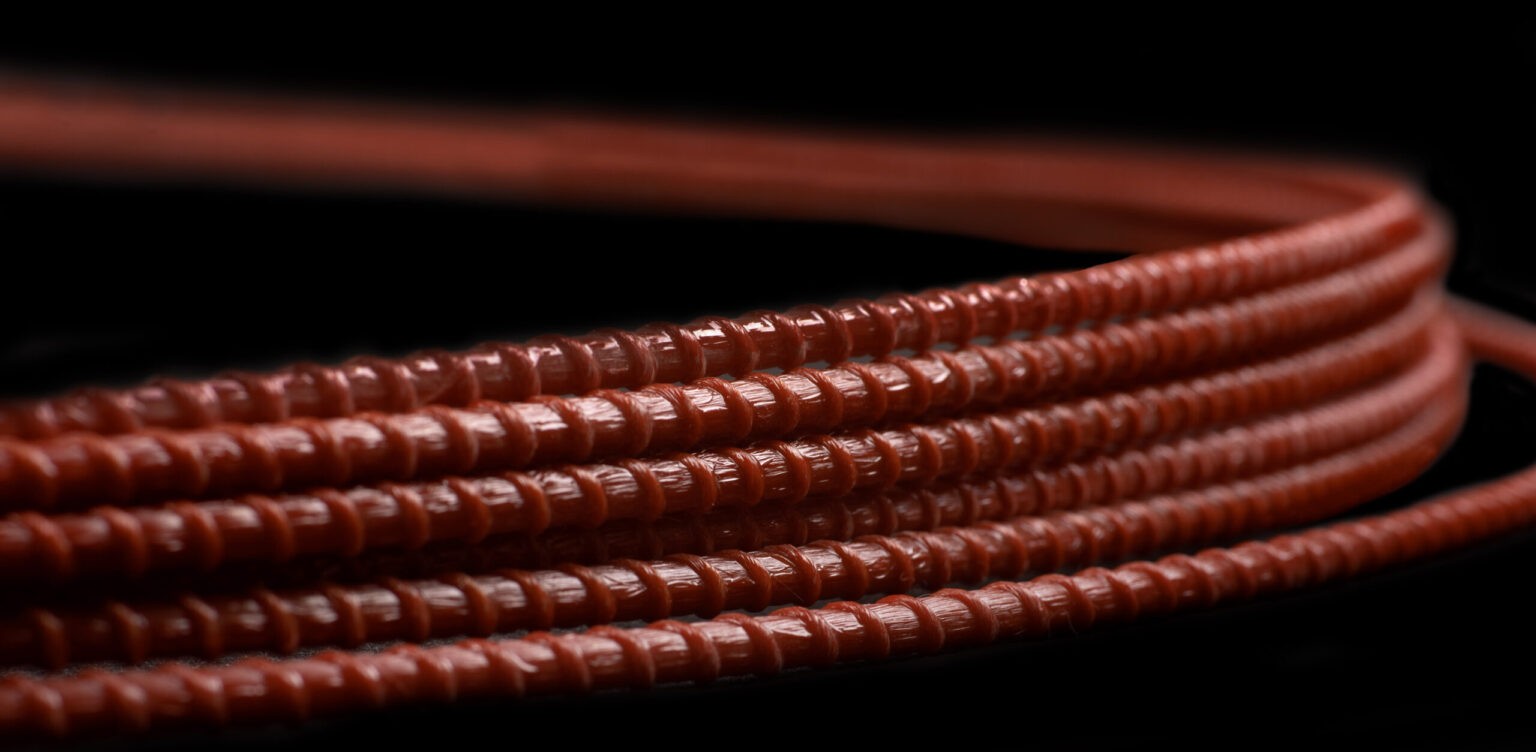

EpsilonRebar provides accurate strain and precise crack measurements over its entire length. On the other hand, it acts similar to a GFRP rebar with standard diameter of ø5 mm. Thanks to its high stiffness and tensile strength, it can perform a dual function: sensing and reinforcing simultaneously.

EpsilonRebar provides accurate strain and precise crack measurements over its entire length. On the other hand, it acts similar to a GFRP rebar with standard diameter of ø5 mm. Thanks to its high stiffness and tensile strength, it can perform a dual function: sensing and reinforcing simultaneously.

It measures both in compression and tension without pretensioning.

The sensor is designed for direct embedding in new structures (concrete or soil) or for installation in existing structures (e.g. in grooves in concrete). High robustness and resistance to mechanical loads and environmental conditions make EpsilonRebar ideal for in-situ applications within construction sites or existing infrastructure. It is also able to withstand short-term high temperatures during asphalting.

The sensor is designed for direct embedding in new structures (concrete or soil) or for installation in existing structures (e.g. in grooves in concrete). High robustness and resistance to mechanical loads and environmental conditions make EpsilonRebar ideal for in-situ applications within construction sites or existing infrastructure. It is also able to withstand short-term high temperatures during asphalting.

EpsilonRebar Advantages

Physical Quantities Measured

DSS

Strain and crack

Strain and crack

DTS

Temperature

Temperature

DAS

Vibrations (strain rate)

Vibrations (strain rate)

Typical Materials

Concrete

Soil

Steel

Composite

EpsilonRebar Application Areas

Structures | Bridges | Piles | Slurry walls | Roads | Dams | Embankments | Pipelines | Tunnels | Railways | Earthworks | Geotechnics | Landslides | Minings | Laboratories… and more

Prestressed concrete beam with EpsilonRebar

Road embankment with EpsilonRebar

Application of EpsilonRebar on a steel gas pipeline

Application of EpsilonRebar in a smart concrete highway

EpsilonRebar Technical Specifications

Strain resolution

1 μɛ

Strain range – both in compression and tension

±2%

Elastic modulus

50 GPa

Tensile strength1

fu > 1 100 MPa

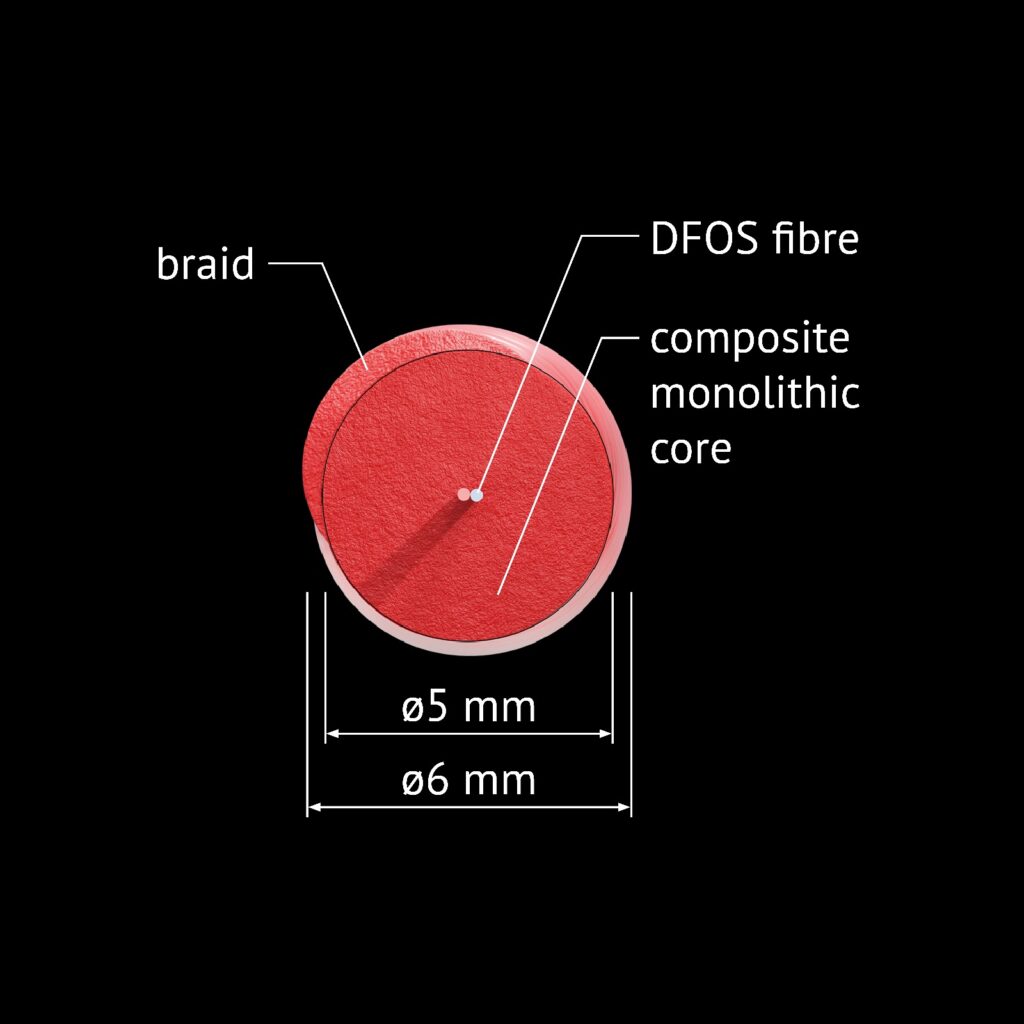

Sensor diameter2

Ø5 mm

Bending radius

400 mm

Sensor mass

45 kg/km

Unidirectional outer braid

yes

Operating temperature3

-20 to +100°C

Core material

GFRP (glass fiber + epoxide)

Scattering compatibility

Rayleigh, Brillouin, Raman

Number of sensing fibres4

2

Type of the fibre5

single-mode SMF 9/125

Attenuation6

< 0.3 dB/km

Sensor length7

up to 1 km

1 According to ISO 10406-1 for rods with diameters up to 12 mm

2 Standard (other diameters available on request)

3 Standard (extended temperature range available on request

4 Standard (more fibres available on request)

5 Standard (other fibres available on request)

6 At 1550 nm wavelenght

7 Sensors can be connected in series

2 Standard (other diameters available on request)

3 Standard (extended temperature range available on request

4 Standard (more fibres available on request)

5 Standard (other fibres available on request)

6 At 1550 nm wavelenght

7 Sensors can be connected in series

EpsilonRebar Installation

Each installation should be designed individually, taking into account specific requirements and local conditions. However, typical methods include:

1. Embedding inside new structures (concrete or ground). This approach is best because it ensures optimal bonding properties, natural protection against mechanical damage and direct sunlight influence. It also allows measurements to be taken from a true strain-stress state and offers the best aesthetics (no visible components on the surface).

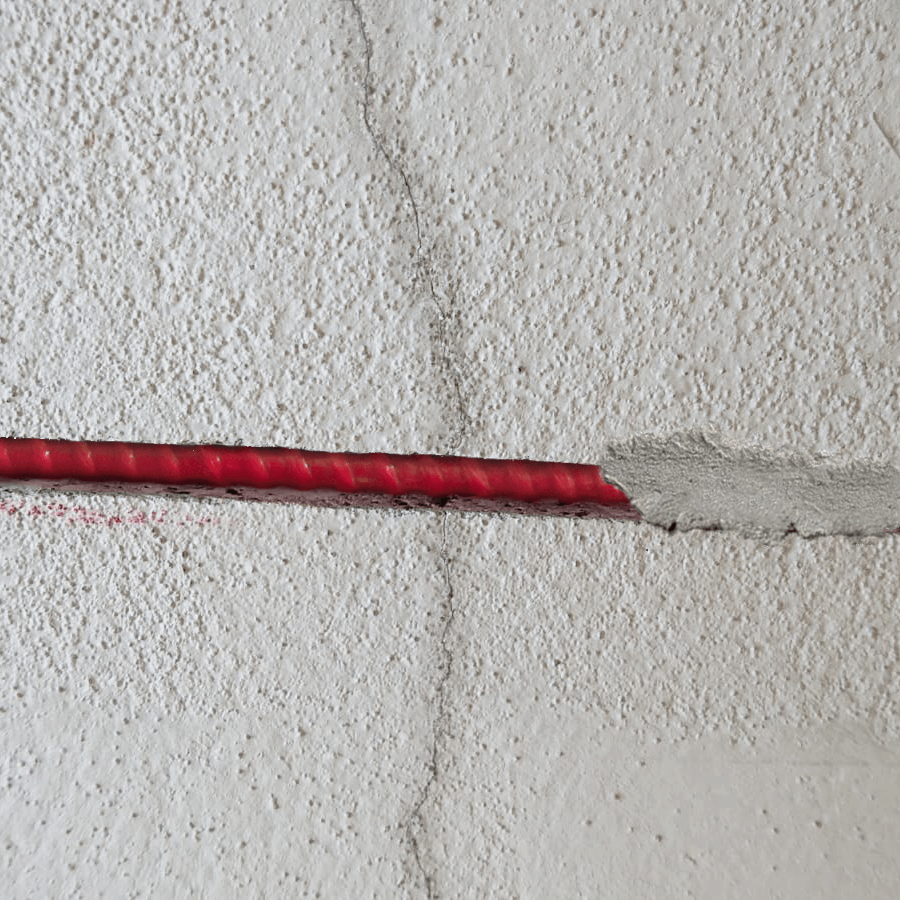

2. Installation in near-to-surface grooves for existing structures. This method requires the preparation of the surface by cutting a grove, the size of which depends on the sensor diameter. It is then filled with a chemical anchor just before mounting the sensor. This method offers similar advantages to embedding.

3. Bonding directly to the sanded, cleaned and degreased structural surface. This approach is relatively simple, but has several drawbacks in terms of durability, resistance and sensitivity to external conditions. It can therefore only be used for short-term measurements with stable thermal conditions. It is also important to choose a suitable adhesive.

Embedding inside new structures (concrete or soil)

Installation in near-to-surface grooves for existing structures

Embedding inside the soil structure

EpsilonRebar FAQ

When to use the EpsilonRebar and when to use the EpsilonSensor?

What is the main difference between EpsilonRebar and EpsilonSensor?

When to use the EpsilonSensor and when to use the EpsilonRebar fiber optic sensor?

Can I use EpsilonRebars instead of rebars in concrete beams?