Distributed fibre optic sensing vs. conventional spot gauges

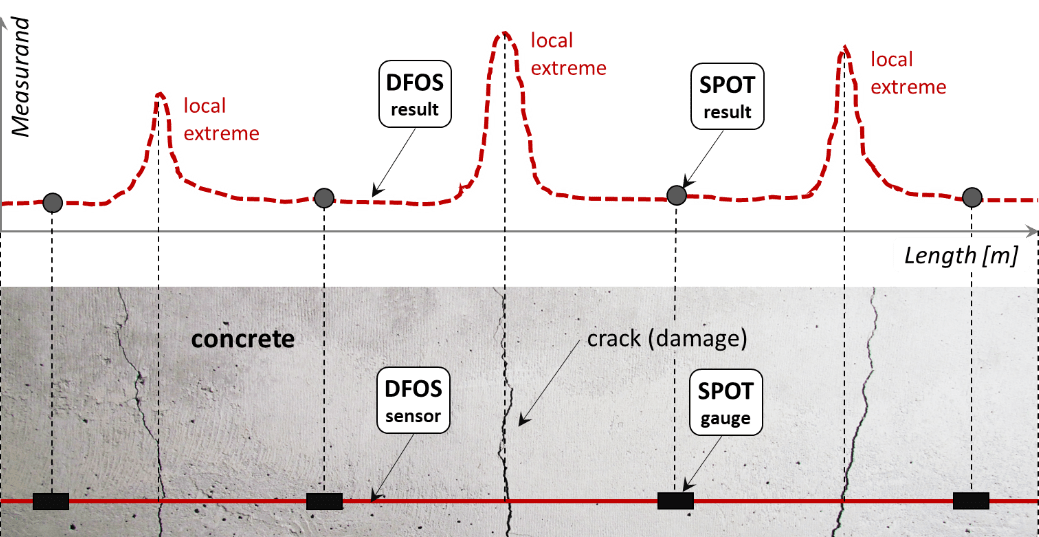

The key feature of this technology and its main advantage over conventional spot gauges is the ability to make distributed measurements, i.e. continuously over the entire length of the sensor. In this way, the most important goal of structural health monitoring – the direct damage detection – can finally be achieved.

Don’t struggle to find the best locations for spot gauges – just monitor the entire length of the structure and never miss extreme values associated with:

Don’t struggle to find the best locations for spot gauges – just monitor the entire length of the structure and never miss extreme values associated with:

• cracks

• damage

• stress concentrations

• leaks

Instead of a single number in a single location – get the whole profile to see the complete picture and understand the true behaviour of your structure!

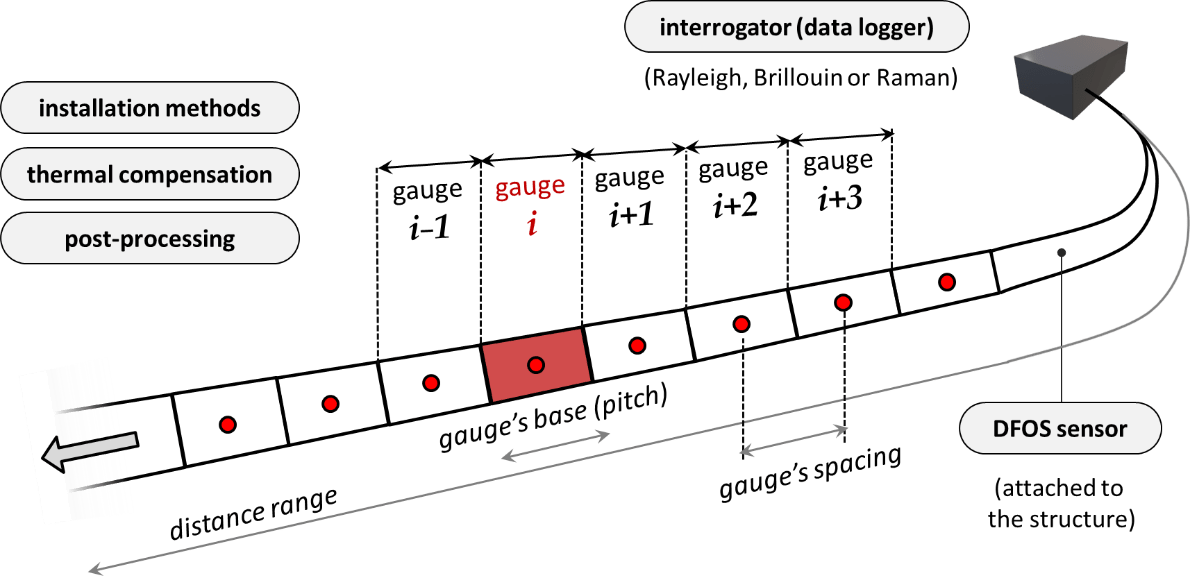

The entire DFOS system consists of the optical interrogator (using Rayleigh, Brillouin or Raman scattering) and the sensors, which are a key component. While the interrogator can be easily replaced, the sensors interact with the monitored structure throughout its lifetime and must provide reliable, undisturbed and trustworthy data – safety first!

Nerve-Sensors are the solution to this challenge

Despite its excellent measurement capabilities, it is worth remembering that DFOS is not a ‘plug and play’ technology. It requires individual analysis of the type of: