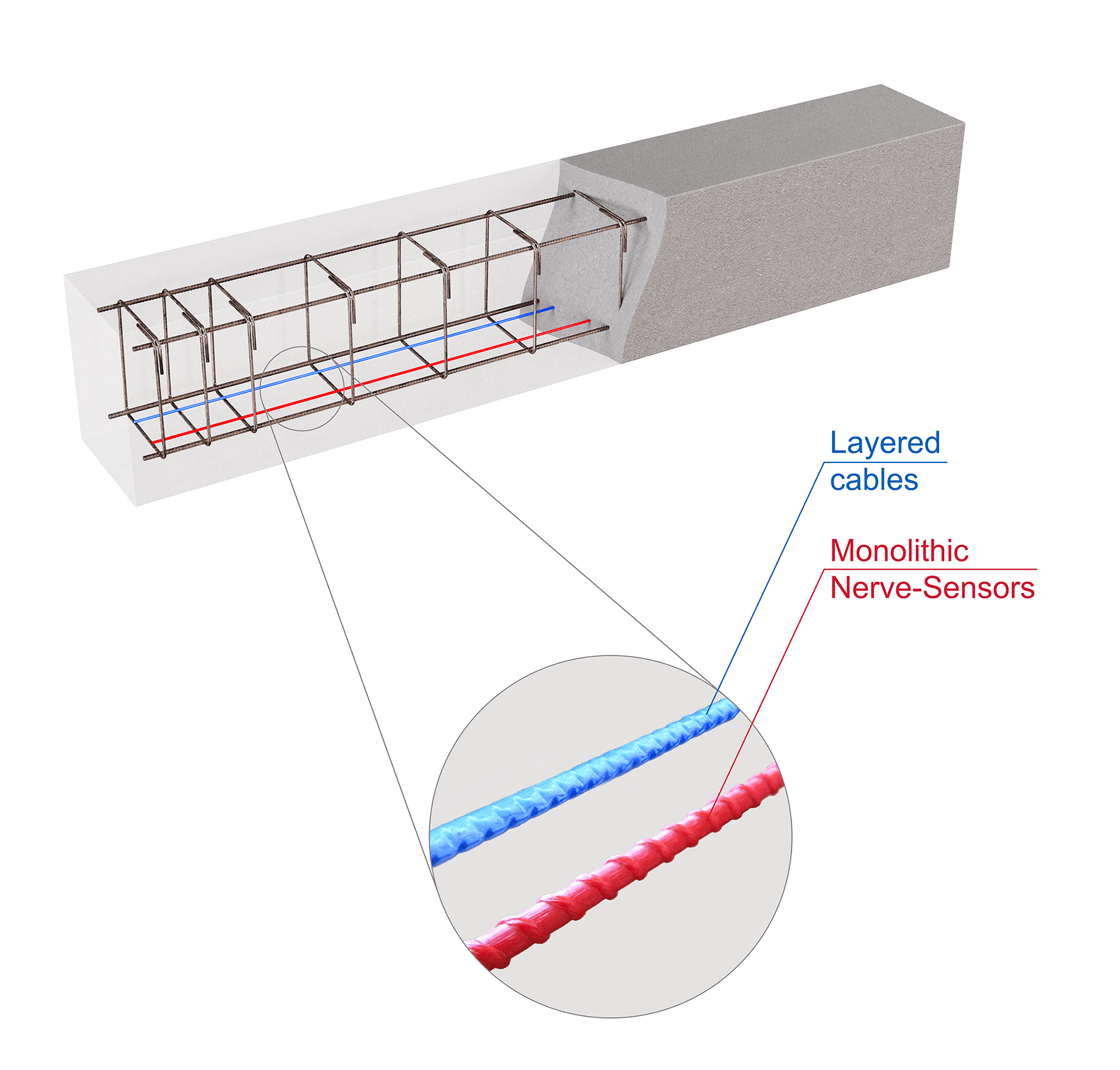

Monolithic sensors vs. layered cables – sense the difference!

Layered cables

Monolithic Nerve-Sensors

multiple layers causing the slippage

poor quality data because the strains in the fibre are being averaged and do not correspond to structural strains

monolithic core with no layers and no slippage

the most precise and detailed measurements because of the undisturbed strain transfer mechanism

low measurement range up to 1%

risk of failure when measuring high strain or cracks

the largest measurement range ±4%

safe measurements of high local strains and cracks

pre-tensioning is required for compression

challenging and sometimes impossible on site

no need for pre-tensioning

measurements are possible both in compression and tension zones

made of plastic & steel layers with unknown material properties

these materials yield fast and interact with each other making physical interpretation difficult

made of single elastic composite core with known material properties

for easy and straightforward data interpretation

originally designed to remember events

using them is risky to monitor the actual state of the structure

designed for structural health monitoring

can assess the actual state of the structure

challenging thermal compensation

thermal deformation of multiple layers can cause additional mechanical strains in the sensing fibre

convenient thermal compensation

monolithic structure can be easily compensated for with a single and linear coefficient

usually smooth outer surface

does not provide appropriate bonding of the sensor with surrounding concrete or ground

outer surface with braid to improve bonding

when measuring strains inside the concrete or ground

flaccid & easy to yield

cannot be used as a substitute for reinforcement in concrete or ground

high strength and stiffness

can be used simultaneously as a sensor and as a reinforcement for concrete or ground

challenging installation

significant waving because of no bending stiffness, sensitivity to localised pressures from cable ties

easier installation

limited waving because of bending stiffness, resistance to localised pressures by cable ties

Monolithic sensors vs. layered cables – sense the difference in data!

Don’t risk the safety of your structure by misinterpreting its true technical condition.

Read Layered sensing cables vs. monolithic DFOS strain sensors

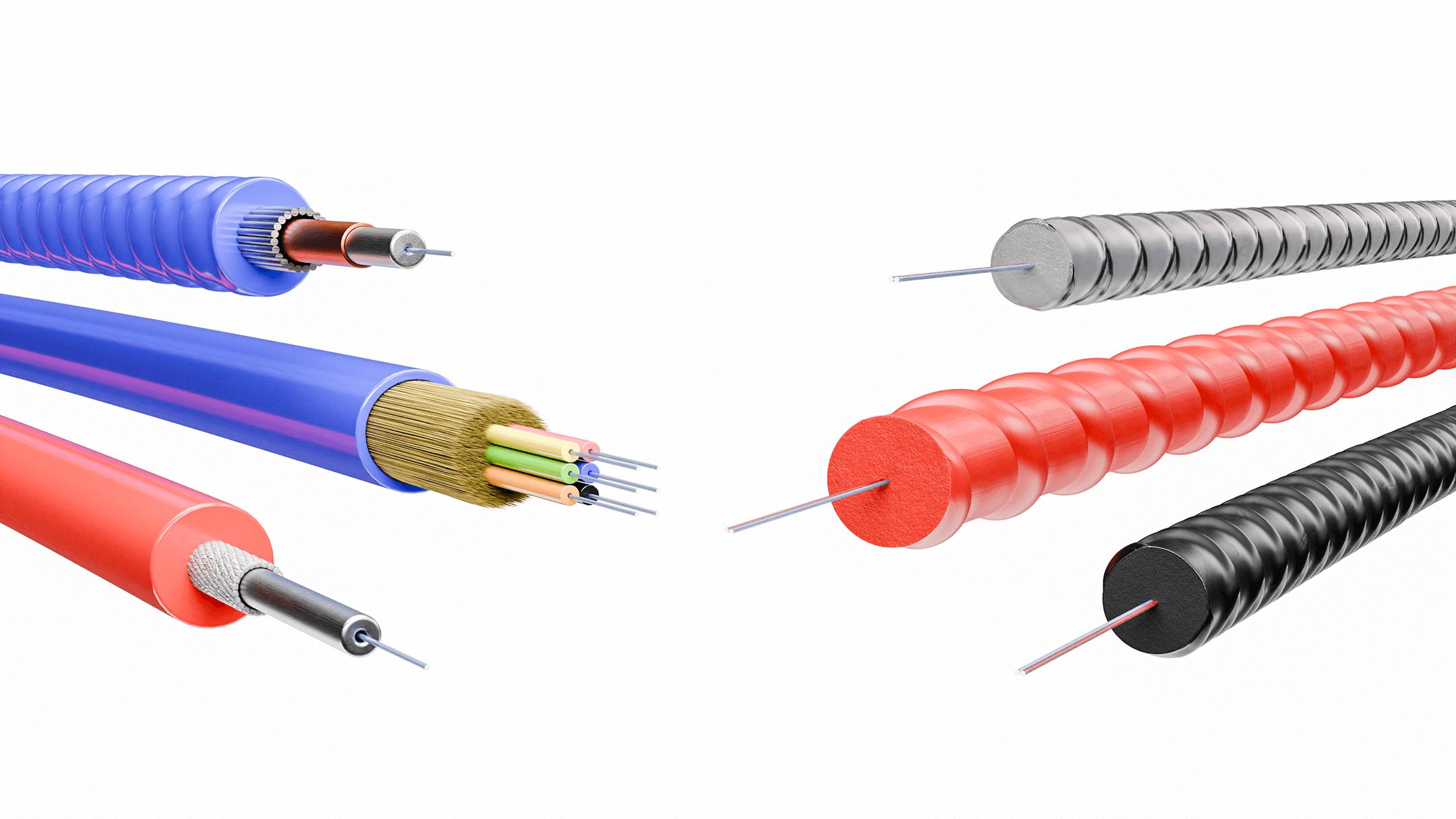

Monolithic sensors vs. layered cables – sense the difference in sensor cross section!

Cables and sensors are not the same!

As opposed to layered cables, monolithic Nerve-Sensors offer considerably improved measurement quality.

The most important feature is a single-material cross section, ensuring precise transfer of strains from the structure to the sensing fibre. Nerve-Sensors allow for detection of the smallest changes in structural behaviour, while on the other hand offer the largest measurement range ensuring their safe operation throughout the entire lifetime of the monitored structure. As opposed to sensing cables, no layers means no internal slippage and no “smoothing” the strains in the fibre, especially when high gradients (e.g. crack-induced) are expected.

Nerve-Sensors can also measure in compression and tension zones without the need for challenging (and sometimes impossible) pre-tensioning on site. Monolithic core of the sensors allows for simple thermal compensation, trusted data and easier interpretation.

Read the article, which details the test carried out on a concrete beam. See more: Crack Shape Coefficient: Comparison between Different DFOS Tools Embedded for Crack Monitoring in Concrete

Left side – Layered cables, right side – Monolithic sensors. A single-material cross section and monolithic core = improved measurement quality and trusted data with Nerve-Sensors

Each project is individual – sense the difference with Nerve-Sensors!

In particular, our support team can provide advice on: